Why? Machine Builders Experience More Competition Than Ever

In today’s world, Machine Builders or OEMs, experience more competition than ever due to Industrial companies’ or Asset Owners’ continuous effort to reduce their capital expenditure and, as a result, turn to lower-cost alternatives from other regions.

At the same time, Asset Owners, require a machine or device that will provide them with more insights and is easy to integrate into their infrastructure. Machine Builders are driven to offer smarter equipment, devices, and related services to meet higher expectations and confront price pressure.

AI on Chip and Edge

UReason offers multi-level deployment: AI deployed on chip (embedded), on edge, on premise or in the cloud. With our software running on chip and edge, we can include all machine data for a superior analysis and enable autonomous machines. And we have made it very scalable. You are able to manage 1000s of assets on edge and cloud level by using one scalable template.

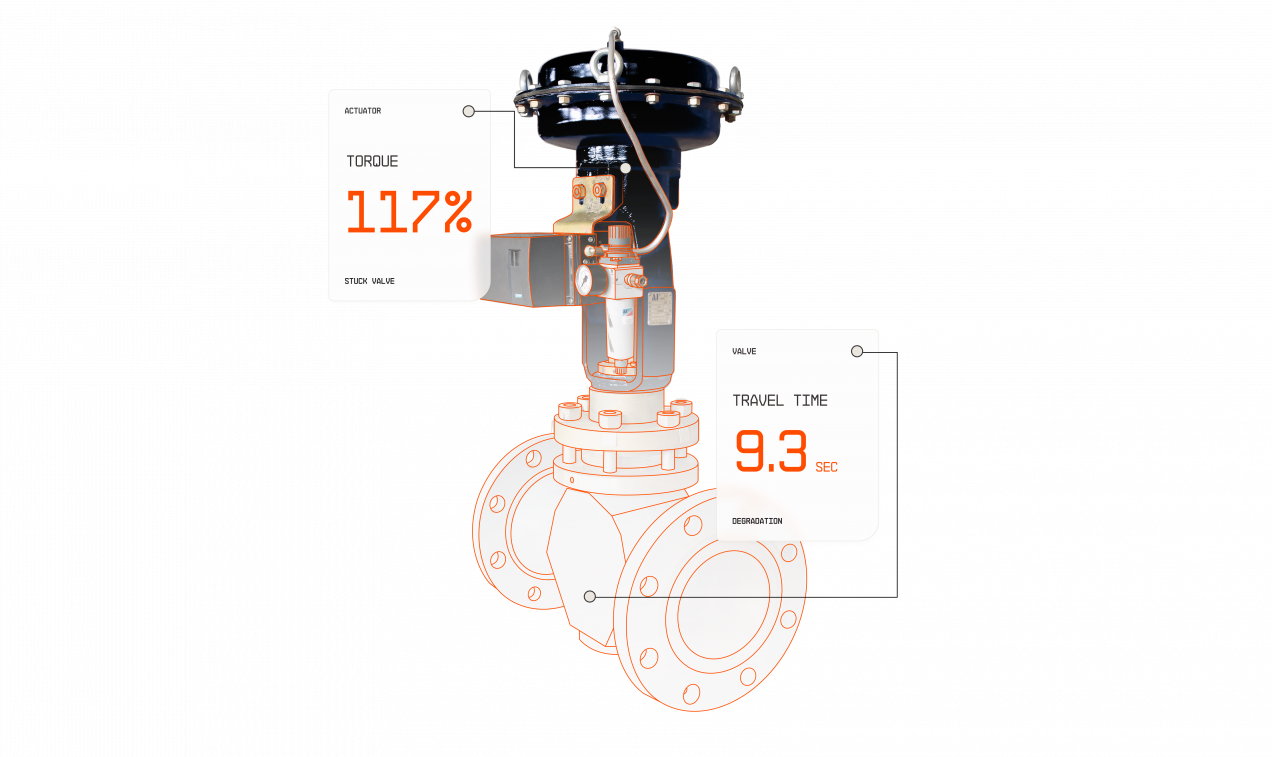

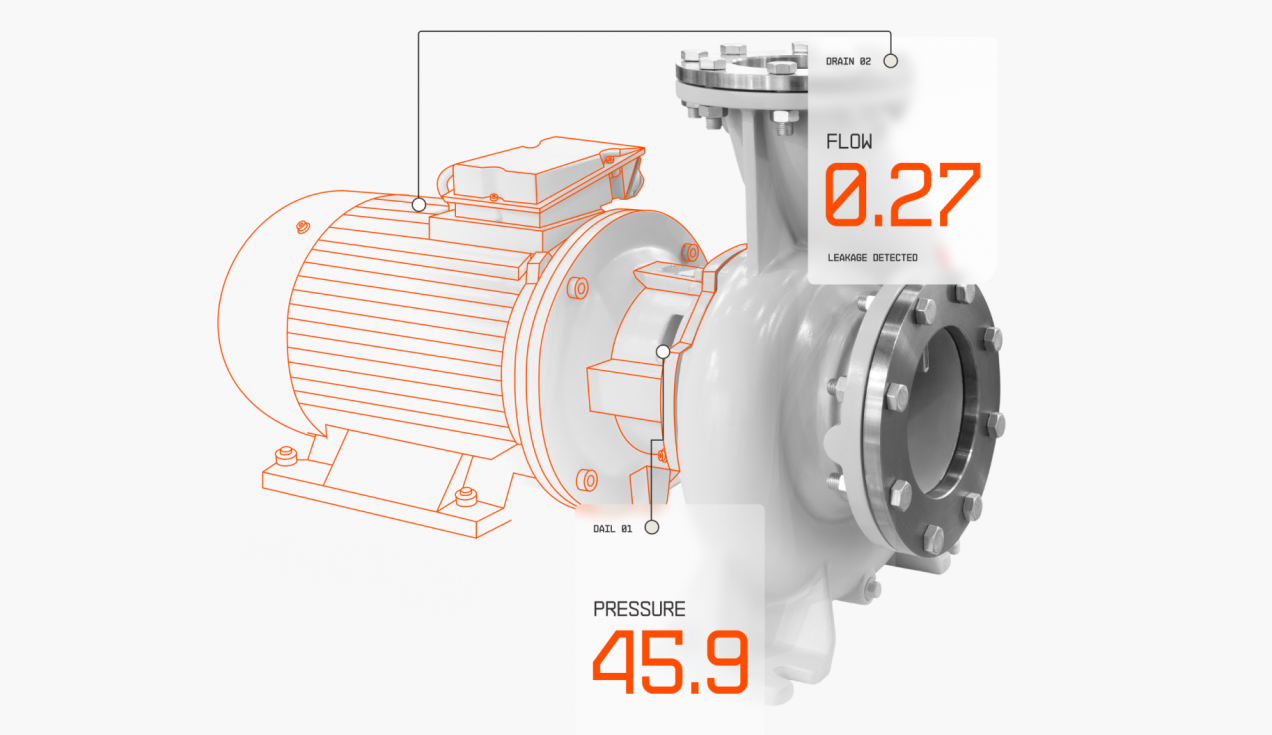

Library of Digital Twins of Your Machines

With APM Studio you do not have to start from scratch. Machine builders can benefit from the digital library of the most common machines and equipment in the industry as a starting point. We have many digital twin models of pumps, valves, actuators, compressors, flow meters, turbines, motors and all other most popular assets.

Digitalise and Protect Your IP

Your specific Machine Expertise can be translated into analytical and causal models which run on real-time data. Adding Machine Learning to these models will provide an accuracy level above 95%.

Unlike many other AI companies, the machine builder owns his data and custom models. The other advantages are that these models provide transparency and have versioning.

How to Make a Digital Twin of a Pump?

FOCUS-ON Case Study

FOCUS-ON is the joint-venture of SAMSON and KROHNE. Both frontrunners have combined forces to launch FOCUS-1. A smart combination of a control valve and a flow meter. With the support of UReason and UReason’s APM Studio, they were able to accelerate the development process of building a unique product with the integration of (embedded) diagnostic functions and artificial intelligence.

“With FOCUS-ON, we are taking a decisive step towards the autonomous factory that can produce autonomous while also autonomously optimizing.”

– FOCUS-ON

Facts About Us

million

The biggest asset base served per client

million

The highest volume of data we can handle – Used to dealing with Zettabytes and 1 Megahertz

meters underground in a mine

The most interesting place we ran our software in

Interested in Obtaining a Faster Time to Market?

- Creating a Minimum Viable Product (MVP) to test with selected customers and demonstrate viability

- Using the different building blocks from our software to drastically reduce your time to market.

- Benefiting from our experience on how to vertically integrate data, information, and insights from the device to the execution level.

- Creating cross-functional teams by combining Engineering, Data Science, IT, and Software Development expertise.

- Using 2-week sprints with concrete deliverables like prototypes ad demonstrators.

UReason Test Center

The UReason Test Center is part of the Flow Center of Excellence, Dordrecht, in The Netherlands.

It offers a water loop, built on the model of EuroLoop, with a ‘real life’ (process) environment for dynamic testing of prototypes and products. More than 15 vendors have their equipment already installed.

- Install your device in a matter of hours

- Collect all the data from your devices and unlock its value

- Create digital models

- Develop machine to cloud integration

Vendors at the Test Center

More than 15 vendors have their equipment already installed. Interested to test your device?