Company Introduction & Situation

Company introduction: Yara International is the world’s leading crop nutrition company and a provider of environmental and agricultural solutions with 26+ production sites spread across the globe. Yara is leading the way and is a digitalization lighthouse in the industry.

The Ferrara site in Italy includes several main production units: ammonia and urea production plants. There is also a CO2 liquefaction unit, an argon recovery unit and an ammonia solution plant, all connected to the main ammonia production plant.

The challenges: With many critical valves in this ammonia production plant, it is important to understand their health status to avoid unexpected breakdowns and costly process downtime. Also, the planning of turnaround activities can become a hurdle because of the high number of valves and tight schedule, so knowing which valves to focus on is essential.

Challenges:

- Understandng the health status of all control valves

- Avoiding costly unexpected production downtime

- Planning of turnaround activities with tight schedule

- Selecting the right valves for Turnaround: fact-based, on the basis of OT data

Our Solution

UReason’s Control Valve App (CVA) was selected to do a project for 155 control valves with varying criticality, applications and manufacturers like Parcol, Metso, Fisher and so on.

CVA provides comprehensive monthly reports that provide insights into the health status of the control valves by assigning a health score for the valve and listing dysfunctions that have happened during the reporting period. Notifications range from warnings to alarms based on their severity.

In enterprise deployment, notifications are integrated automatically into Yara’s Digital Production Platform (DPP).

Based on the installation dates of the control valves and their actuators, CVA’s algorithms calculate the Remaining Useful Life taking into consideration their operating context. This supports Yara’s on-site reliability experts to understand which valves need maintenance during turnaround and which ones will operate well without foreseeable issues until the next turnaround cycle.

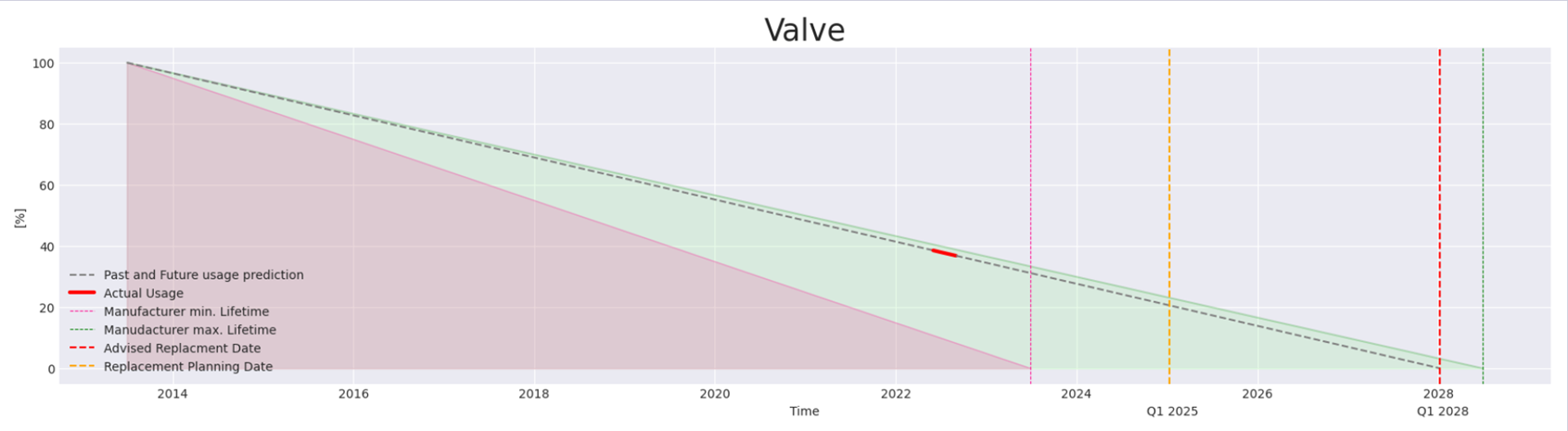

How CVA Predicts Valve Remaining Useful Life (RUL)

CVA calculates the Remaining Useful Life (RUL) of each control valve by combining installation data of the valve and actuator with the actual operating conditions and usage context.

These dynamic RUL insights support fact-based turnaround planning and targeted maintenance decisions, helping teams focus on the valves that truly require attention.

Customer’s Feedback

During the monthly review sessions with UReason and Ferrara’s on-site valve experts, it became apparent that the CVA findings on bad-performing valves were aligned and validated by the experiences of Yara’s on-site experts.

Also, the CVA showed increasing stiction in the most critical valve of the plant, enabling experts to have data-based insights into the condition of the valve and know when actions should be taken.

Understanding the condition of the valves allowed us to revise the priority list for turnaround and we feel confident that the valves in the list are chosen correctly and need maintenance, saving money and time by having a focused list and avoiding unnecessary replacements.

Download Control Valve App brochure

If you want to see how the CVA works, and how you can best use it, you can download a brochure here.