In the first 40 minutes, we discuss:

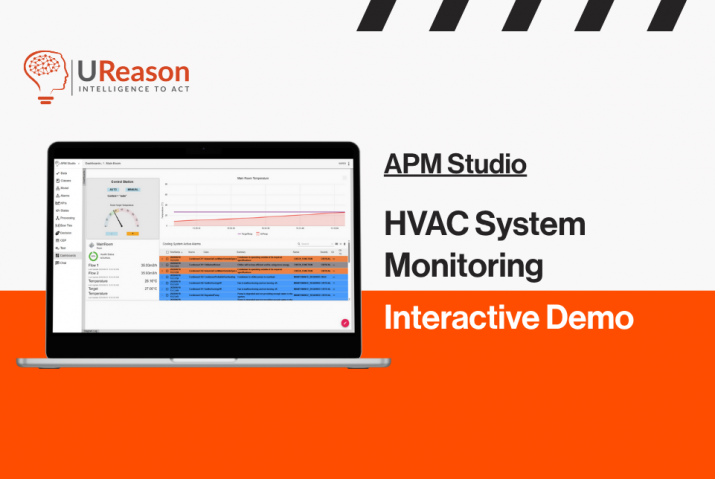

- What is the project flow of APM projects

- How to select the critical assets

- How does the data collection work

- How to choose the most fitting asset failure models

- How to deploy Predictive Maintenance solutions

The webinar session is followed by a 20-minute Q&A session

The Power of Predictive Analytics on Critical Assets

Leading companies are leveraging predictive analytics to reduce equipment failures, increase reliability and reduce maintenance costs. The business cases are significant with larger companies earning millions of euros in savings.

In this webinar, we will explain how leading companies are piloting and implementing predictive analytics technologies.

Speaker

Jules Oudmans - Director Consultancy

Jules Oudmans is one of the co-founders of UReason. He is a seasoned professional active in the field of operational intelligence and real-time analytics. He has set vision and supported early adaptors and co-visionaries in Oil & Gas, Petro(chemical), Utilities, Pulp & Paper, Defense and Telecom industries at companies such as Halliburton, BP, Motorola, Siemens, Shell, Cargill, Lyondell and BG/Transco.

Check out more of our events

If you enjoyed this content, check out more of our previous webinars on several topics related to Asset Performance Management!