A positioner is a device used in conjunction with control valves to precisely control the valve’s position based on response to the input signal received from a control system. It ensures that the valve moves to the desired position accurately and quickly.

Here’s how it works: The control system sends a signal to the positioner, indicating the desired position of the valve. The positioner then compares this signal to the actual position of the valve and adjusts the valve’s actuator accordingly to achieve the desired position (it is a small control system in itself).

Positioners are commonly used in situations where precise control of flow, pressure, or other process variables is critical. Precise as the desired set-point required from the control valve may not be reached due to fluid forces and friction. Positioners are especially useful in processes where the operating conditions may vary or where tight control (minimal error) is required to maintain product quality, safety, or regulatory compliance.

Some common applications of positioners include:

- Control of flow rates in chemical processing plants, refineries, and power plants.

- Regulation of pressure in gas pipelines, steam systems, and water treatment plants.

- Control of liquid levels in tanks and vessels.

- Modulating control of temperature in HVAC systems and industrial processes.

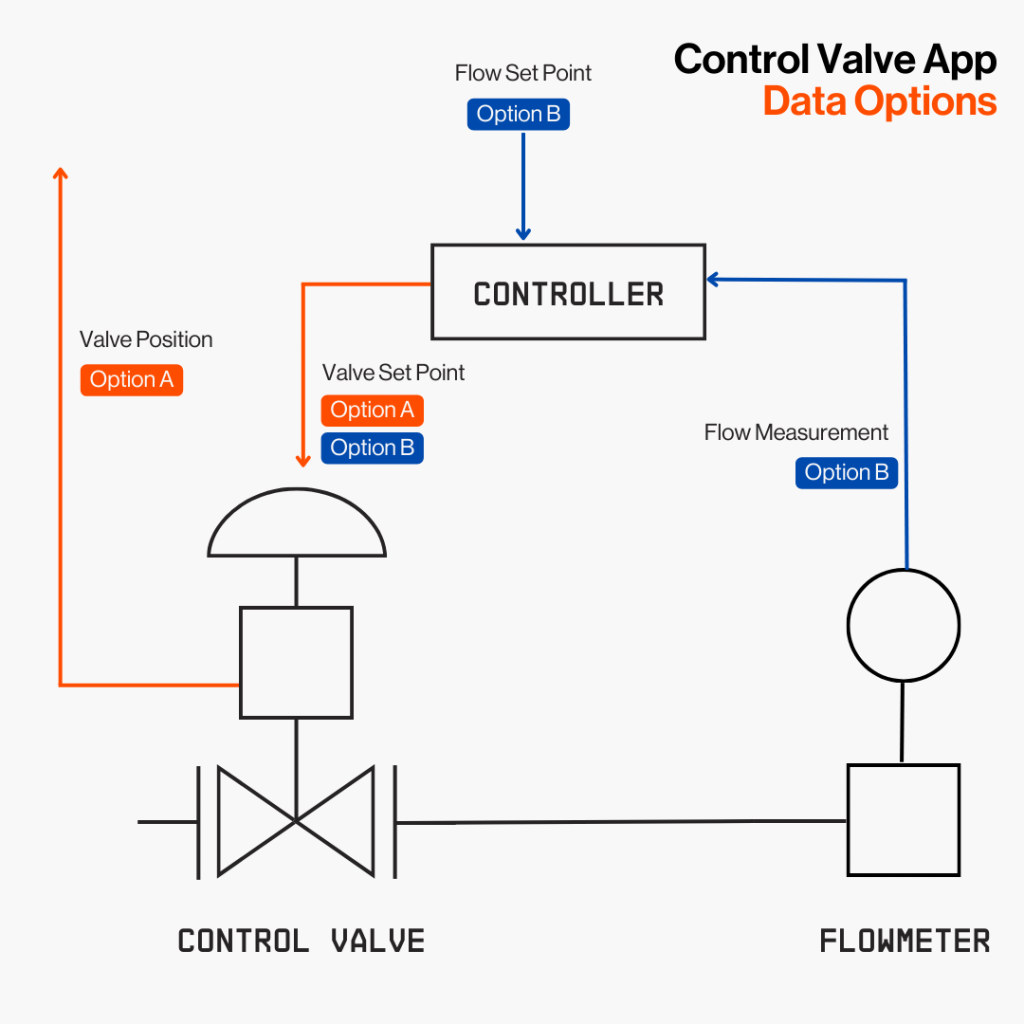

As positioners are used for precise/tight control, the calibration of the control valve positioner is a crucial process and must be done properly for the desired results. In the case of digital positioners calibration may be automatic, often in combination with software packages provided by the OEM. However, in the case of electropneumatic positioners, that translate current-to-pressure, there is generally no automatic calibration capability. Regardless of the availability of a calibration capability you need to keep a close eye on the preciseness of your positioners. This is where the Control Valve App comes in. Based on the data it receives for setpoint (SP or CO) and position (MV):

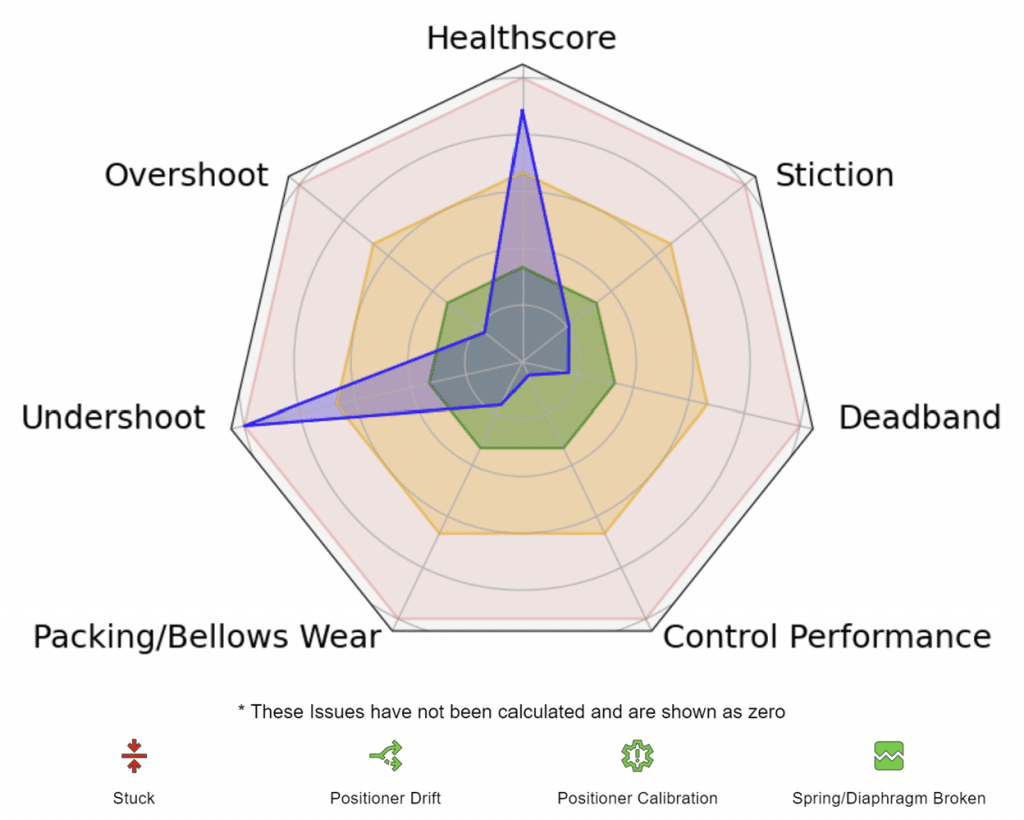

It detects offsets and drifts and notifies these to the user so action can be taken, and the user can move from a preventive inspection schedule to a proactive maintenance regime.

This allows users to detect issues with positioners early, temporarily compensate in the control for these, and drive their processes more accurately leading to improved process efficiency, stability, and safety.