Introduction to ESPR

In July 2024 the European Union adopted a major new law to raise the bar for product sustainability. The Ecodesign for Sustainable Products Regulation (ESPR) — formally Regulation (EU) 2024/1781 — entered into force on 18 July 2024, replacing the older Ecodesign Directive (2009/125/EC) (European Commission).

Unlike the old Directive (which focused only on energy-related products), the ESPR expands the scope to virtually all physical goods placed on the EU market — from textiles or furniture, to electronics, plastics, and many other materials — with only a few exceptions (e.g. food, medicinal products, some living organisms) (Latham & Watkins).

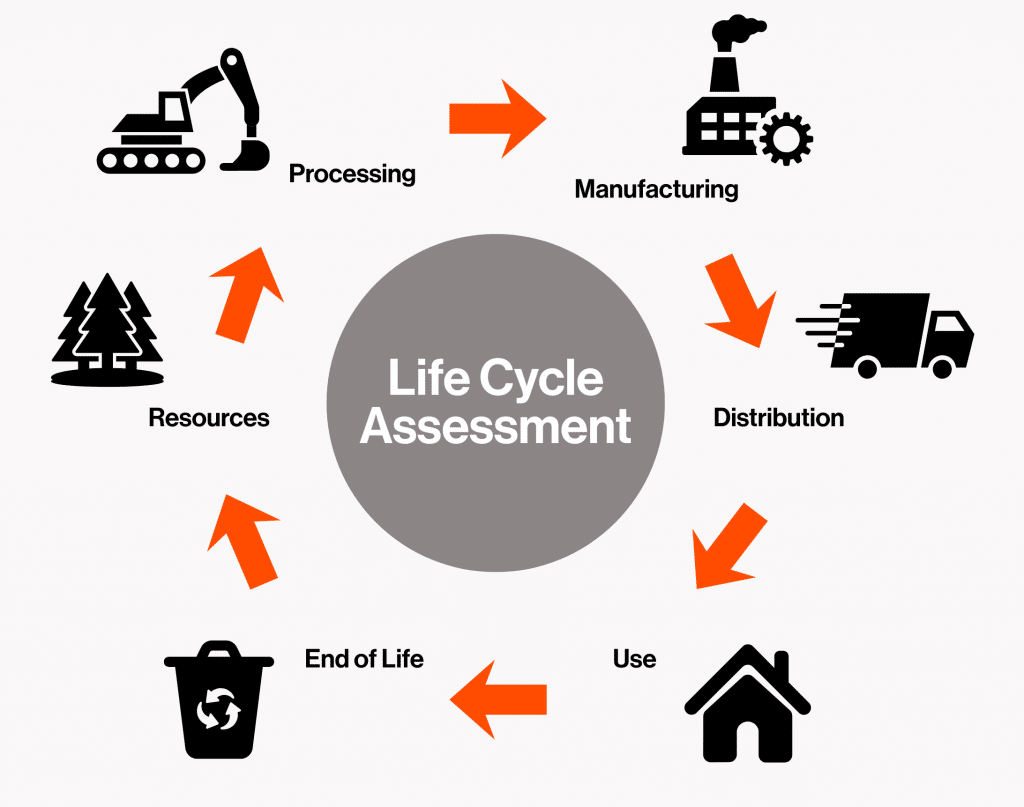

The overall ambition: to make sustainable, circular products the norm. The ESPR seeks to ensure that products are designed and manufactured so that they are more durable, repairable, recyclable, resource-efficient, and have lower environmental footprints during their full lifecycle (Eura AG).

A key innovation under ESPR is the concept of a Digital Product Passport (DPP) — a digital identity for products containing structured information on materials, sustainability data, reparability / recycling instructions, and lifecycle / environmental impact.

What Does ESPR Mean — Stakeholder Perspectives

From an Asset Owner Perspective – Buyers of Assets

- Greater transparency and traceability. Thanks to the DPP, asset owners will have access to rich information about the origin, composition, reparability, recyclability, environmental footprint, and end-of-life instructions of products. This helps make more informed procurement or resale decisions, favoring sustainability and long-term value.

- Better durability and life-cycle value. Products designed under ESPR are expected to be more durable, easier to repair or upgrade, and more recyclable — meaning lower maintenance or replacement costs over time, and potentially higher residual or recycling value. That supports a longer asset lifetime and reduced total cost of ownership.

- Support for circular economy business models. For companies managing large product fleets, assets, or supply chains (e.g. retailers, property managers, public buyers), ESPR encourages reuse, refurbishment, remanufacture — enabling circular, more sustainable business models instead of linear “use and discard.”

- Level playing field and comparability. Because ESPR applies across the EU market, asset owners benefit from comparable information and standards across suppliers — easier benchmarking, easier compliance with internal sustainability goals or procurement policies.

From an OEM / Manufacturer / Producer Perspective

- New design requirements — more constraints but also opportunities. OEMs will need to redesign products to meet ecodesign requirements for durability, reparability, resource efficiency, recyclability, and possibly restrictions on problematic substances. That may increase design complexity, material costs, or manufacturing costs. But it also drives innovation: new materials, modular design, easier maintenance, upgradability, remanufacturing, and circular business models.

- Regulatory compliance & future-proofing. OEMs supplying the EU market (whether based in EU or outside) must ensure their products comply — including creation and maintenance of Digital Product Passports where required. Non-compliance could result in products being blocked from sale.

- Competitive advantage for sustainability frontrunners. Manufacturers who invest early in sustainable design, circularity and transparency may benefit from greater market demand (especially from public procurement), better brand reputation, and potential cost savings over lifetime of products.

- Supply-chain and data requirements. Compliance will require collection of detailed data (materials, processes, lifecycle impacts, recyclability etc.), traceability throughout the supply chain, and possibly collaboration with suppliers and downstream actors — which may require new processes, data infrastructure, and traceability systems.

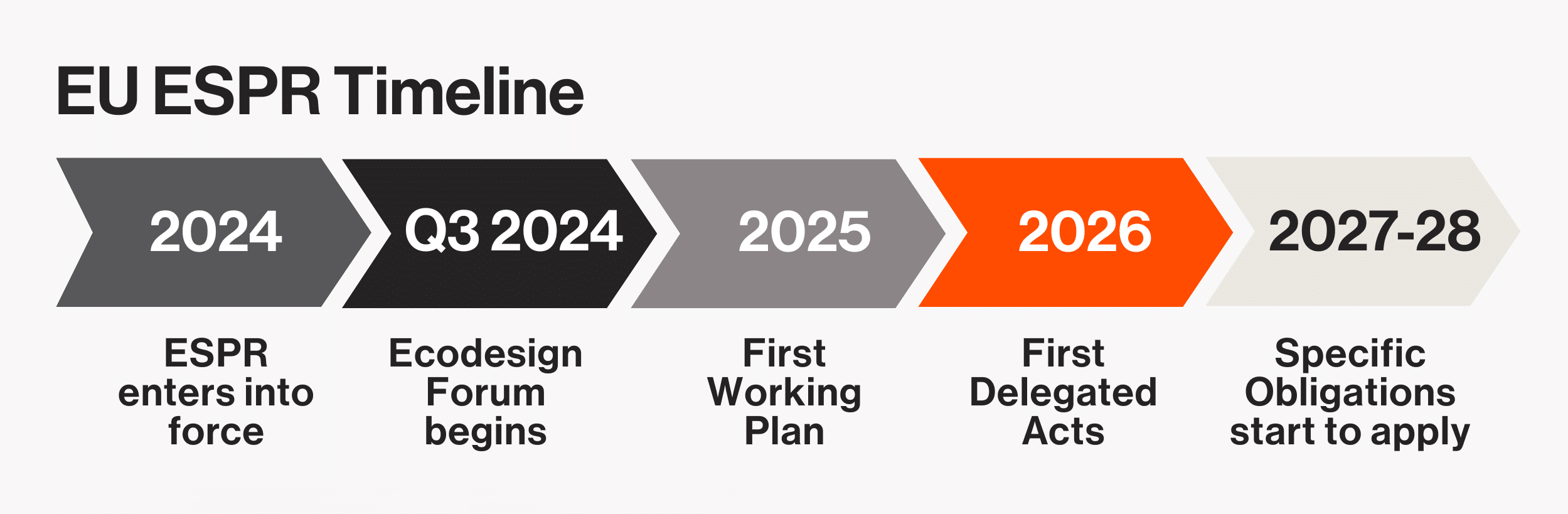

Timeline — When ESPR Applies

Because the ESPR is a framework regulation, it does not immediately impose detailed rules for every product. Instead:

18 July 2024 — ESPR enters into force in the EU (European Commission) .

In Q3 2024 the new Ecodesign Forum was established to consult stakeholders and guide implementation (IEEP AISBL).

By April 2025 (or Q2 2025), the first ESPR & Energy Labelling Working Plan is expected / scheduled — defining which product groups will be prioritised for concrete ecodesign rules.

2026: first delegated acts (i.e. product-specific regulations) are expected for high-impact categories such as textiles, iron/steel/aluminium, furniture, tyres, etc.

2027–2028 (or slightly later): first product-specific ecodesign requirements — including DPP obligations for those categories — will start to apply.

Note: only those products for which delegated acts impose requirements will need to comply (i.e. not all goods at once).

In practice this means: while the ESPR framework is now in law, real compliance obligations will be phased in over the coming years, giving businesses some time to prepare.

How to Implement ESPR — Digital Product Passport & Beyond

Because ESPR is broad and flexible, there is no “one-size-fits-all” approach. But several paths and tools stand out — including the Asset Administration Shell (AAS), as well as other possible approaches.

Digital Product Passport (DPP)

For product groups covered by delegated acts, companies will likely need to create a DPP for each product (or relevant component). The DPP must store structured data: materials used, environmental footprint, recyclability, reparability instructions, presence of substances of concern, end-of-life handling, and possibly unique identifiers.

Responsibility typically lies with the “economic operator” (manufacturer or importer) placing the product on the EU market.

For complex products / supply chains / OEM + suppliers, this may require data collection across the entire supply chain and lifecycle, from raw materials to final disposal.

Asset Administration Shell (AAS) — and other digital asset-management frameworks

The AAS — originally developed in the context of Industry 4.0 / industrial digital twin concept — can serve as a digital container for product metadata (materials, configurations, lifecycle data, component history, maintenance records, etc.). As such, it can be repurposed to hold the DPP data required by ESPR. This makes it a good fit for manufacturing companies that already use AAS for product lifecycle management, maintenance, or digital twin applications.

Beyond AAS, other digital-product-information frameworks or data-management systems may be used. For example: decentralized identity solutions using decentralized identifiers (DIDs) and verifiable credentials (VCs). Recent academic proposals explore how DIDs/VCs could support DPP compliance under ESPR — offering scalable, interoperable, and secure product identity/data management (arXiv).

Alternatively, companies may use cloud-based Product-Lifecycle Management (PLM) systems, or supply-chain traceability / blockchain-based platforms, especially for complex products with many subcomponents or long supply chains. As long as the system can produce and maintain the structured information required (materials, origin, recyclability, lifespan, maintenance/repair metadata, etc.), it can support ESPR compliance.

For outsourced manufacturing or procurement, firms may rely on specialized third-party “DPP-as-a-Service” providers who collect, store, and manage the required data on behalf of manufacturers/importers.

Internal processes & compliance readiness

Implementation isn’t only about IT/data systems — companies should carry out:

- Gap analysis — assess current products vs likely future ESPR requirements (materials, disassembly, repairability, recyclability, data availability).

- Supply-chain mapping — trace material and component origins, gather data from suppliers, and ensure traceability.

- Design & engineering changes — redesign products for modularity, repairability, recyclability, easier disassembly; adopt more sustainable materials.

- Data & documentation infrastructure — set up consistent documentation processes, metadata standards, version control and data-sharing capabilities across supply-chain partners.

- Lifecycle & end-of-life planning — establish processes for refurbishing, recycling, take-back schemes, waste treatment or remanufacture where applicable.

- Compliance monitoring & updates — track delegated acts and working plans from the EU; align product development cycles with upcoming requirements; be ready to update product designs and data accordingly.

Conclusion

The ESPR represents a major transformation in how products are designed, produced, sold — and retired — in the EU. For asset owners, it promises greater transparency, better sustainability, and longer-lasting value. For OEMs and manufacturers, it introduces challenges (data collection, redesign, supply-chain traceability), but also opportunities — to innovate, differentiate, and build circular-economy business models.

Because ESPR is a framework regulation, the real test will come gradually: first with the adoption of product-specific delegated acts, then with concrete requirements and Digital Product Passports. For many businesses, that means now is the time to prepare: perform gap analyses, invest in data and traceability systems (e.g. via AAS, PLM or DPP-platforms), and rethink design, supply chains, and lifecycle management — to align with a more sustainable, circular future.

Need guidance on ESPR and Digital Product Passport readiness?

Schedule a call with Artur Loorpuu, Senior Solutions Engineer in Digitalization, to explore how your organisation can structure product data, improve traceability, and prepare for the delegated acts that will phase in over the coming years.

Let’s explore how we can support your goals!