The Situation

Aquafin is a Belgian utility company responsible for the infrastructure of sewage water purification in the province of Flanders. Aquafin is not only responsible for the operation, but also the financing and expansion of the wastewater treatment infrastructure in Flanders. The Belgian company is responsible for managing 2,500 pumping stations and 318 water treatment plants. Aquafin wanted to predict pump failure and implement a more proactive approach to maintenance on these failed pumps. UReason and MaxGrip join forces with their respective knowledge in predictive maintenance and consulting to optimise processes at Aquafin.

The Challenge

Before the project came about, no use was made of the data of the pumps to predict pump failure. Due to the dependency of the province on Aquafin for the purification of sewage waters, maintenance had to be directly implemented to avoid unwanted discharge in the water, lowering water purity.

If Aquafin would be able to better predict maintenance around working hours, operations will be more efficient, water purity would be increased and general maintenance cost due to unplanned hours would be decreased.

The Solution

UReason offered APM Studio to support Aquafin. With APM Studio, Aquafin was able to:

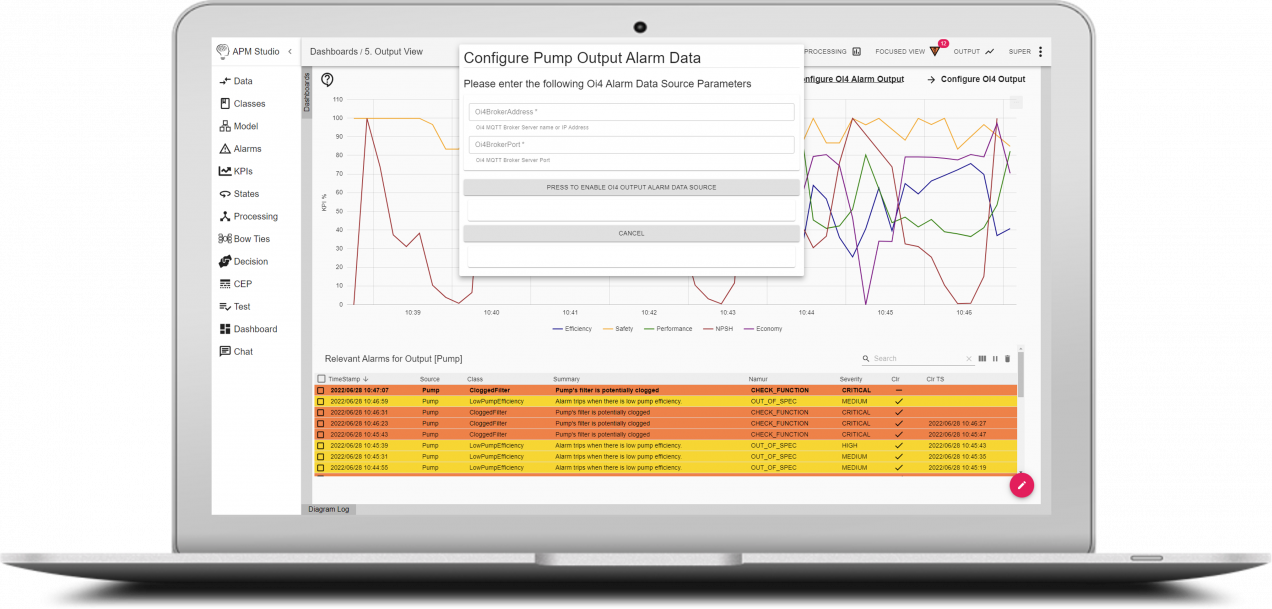

- Run real-time analysis of the root causes of the current flows of events and alarms.

- Create dashboards & insights that can be used to predict failure and avoid or prevent PLC/ SCADA alarming.

- Identify critical issues on pumps 3,5 hours earlier than current PLC/SCADA alarms, lowering the risks of consequential damage due to complete failure of assets and showing that PLC/SCADA alarms were missed previously.

- Create rules to detect a low flow/power ratio and a downward trend on the flow. This results in the use of a probabilistic BowTie model.

The Benefits

- Aquafin transformed from a reactive to a proactive, real-time data driven maintenance strategy.

- Able to identify pump issues 3.5 hours earlier than with standard PLC/SCADA alarming, allowing Aquafin to switch pumps before losing pump capacity or even capability and scheduling maintenance accordingly.

- Reduce 50% in weekend and intervention costs, with further improvements possible in weekend and night hours.

- Save energy and reduce carbon footprint by further implementing data driven maintenance and optimizing processes, helping them reach CSR targets.

- Reduce unavoidable discharges, which keeps water purification levels at 100% and helps Aquafin comply with European requirements.

Learn More About This Solution

Want to know more about the solution and how it can support your production?