Why Change Management Is Essential in Industrial Maintenance

Change management is more than a buzzword. It’s a disciplined approach to guiding organizations from their current state to a more effective one—especially in complex environments like industrial maintenance.

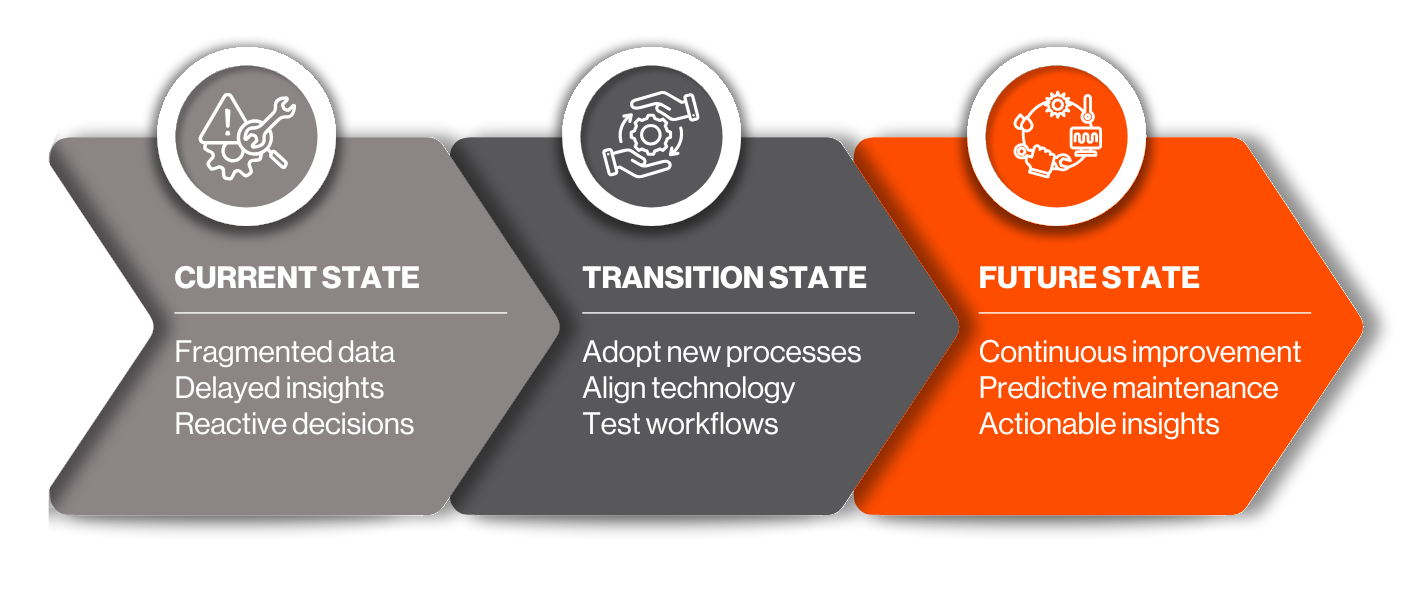

From Reactive to Predictive: Three Operational States

Reactive State: Maintenance teams rely heavily on experience, manual checks, and delayed reporting. Decisions are reactive.

Transition state: New workflows and tools are introduced. Data sources begin to connect. Pilots provide early evidence of success.

Future state: Predictive insights are embedded into daily routines. Teams act earlier, downtime is reduced, and improvement becomes continuous.

Small departmental pilots often spark broader momentum. Once one team proves success—say, by avoiding a last-minute shutdown—others naturally follow. Structured change management makes this repeatable, helping new practices feel familiar and achievable.

5 Steps to Build a Predictive Maintenance Culture

5 Steps to Build a Predictive Maintenance Culture

Adopting predictive maintenance is not just about new tools—it’s a mindset shift. Here’s how departments can start embedding it:

1. Adopt Proactive Decision-Making

Move from reacting to failures toward preventing them. Live asset data allows decisions to be made before issues escalate.

2. Track Leading Indicators

Instead of waiting for breakdowns, watch for early signs like rising motor temperatures or decreasing pressure levels. These subtle changes are often the first clues.

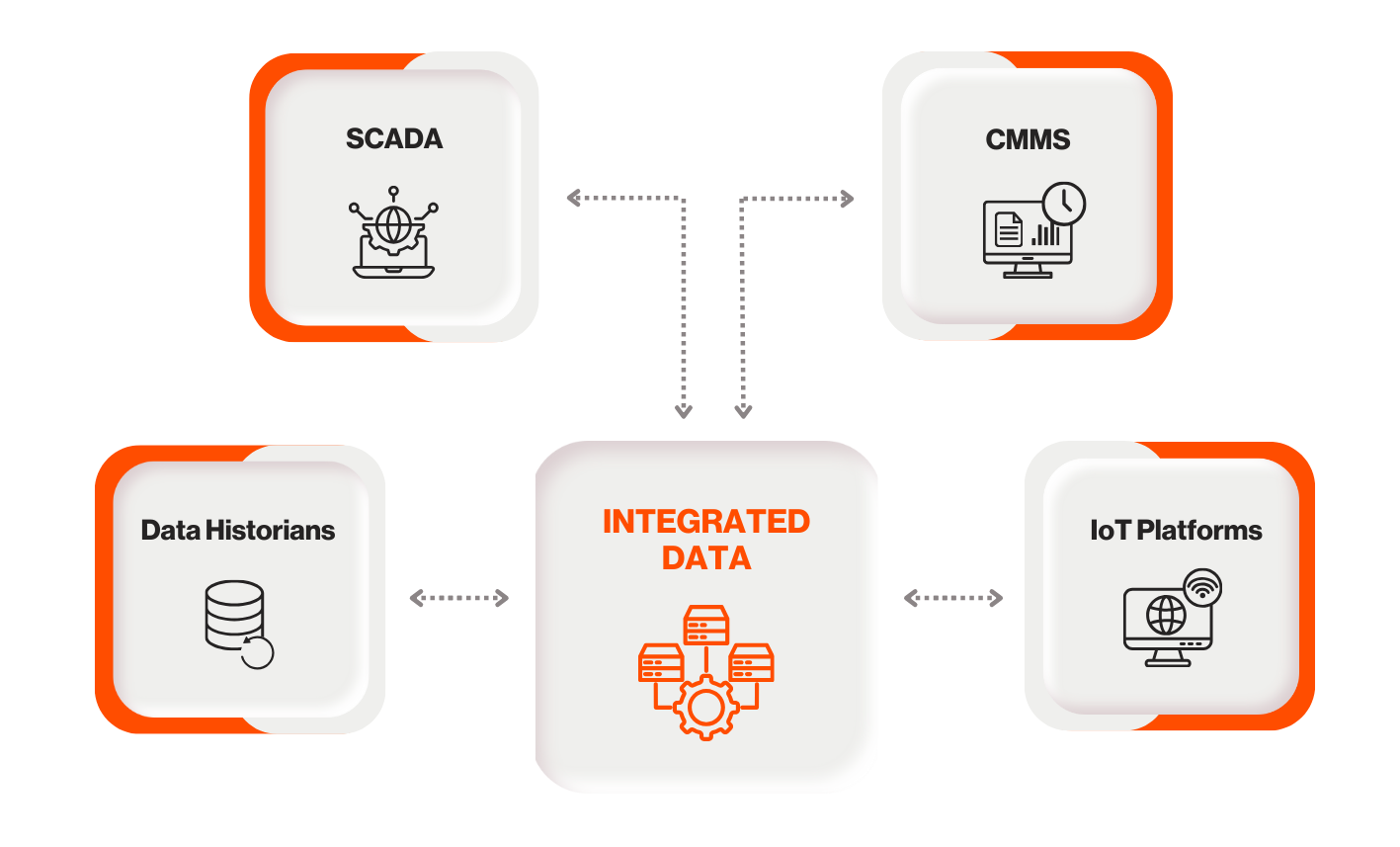

3. Integrate Data Across Systems

Bringing together SCADA, historians, CMMS, and IoT platforms breaks data silos. A unified dataset empowers better decision-making.

Choose one critical asset and apply predictive methods. Demonstrate value. This builds confidence for wider rollouts.

5. Equip Teams with the Right Resources

Training and contextual insights are essential. Teams need tools that highlight actionable information—not just data dumps.

These steps help teams shift their focus from reacting to failures to preventing them, paving the way for more sustainable maintenance practices.

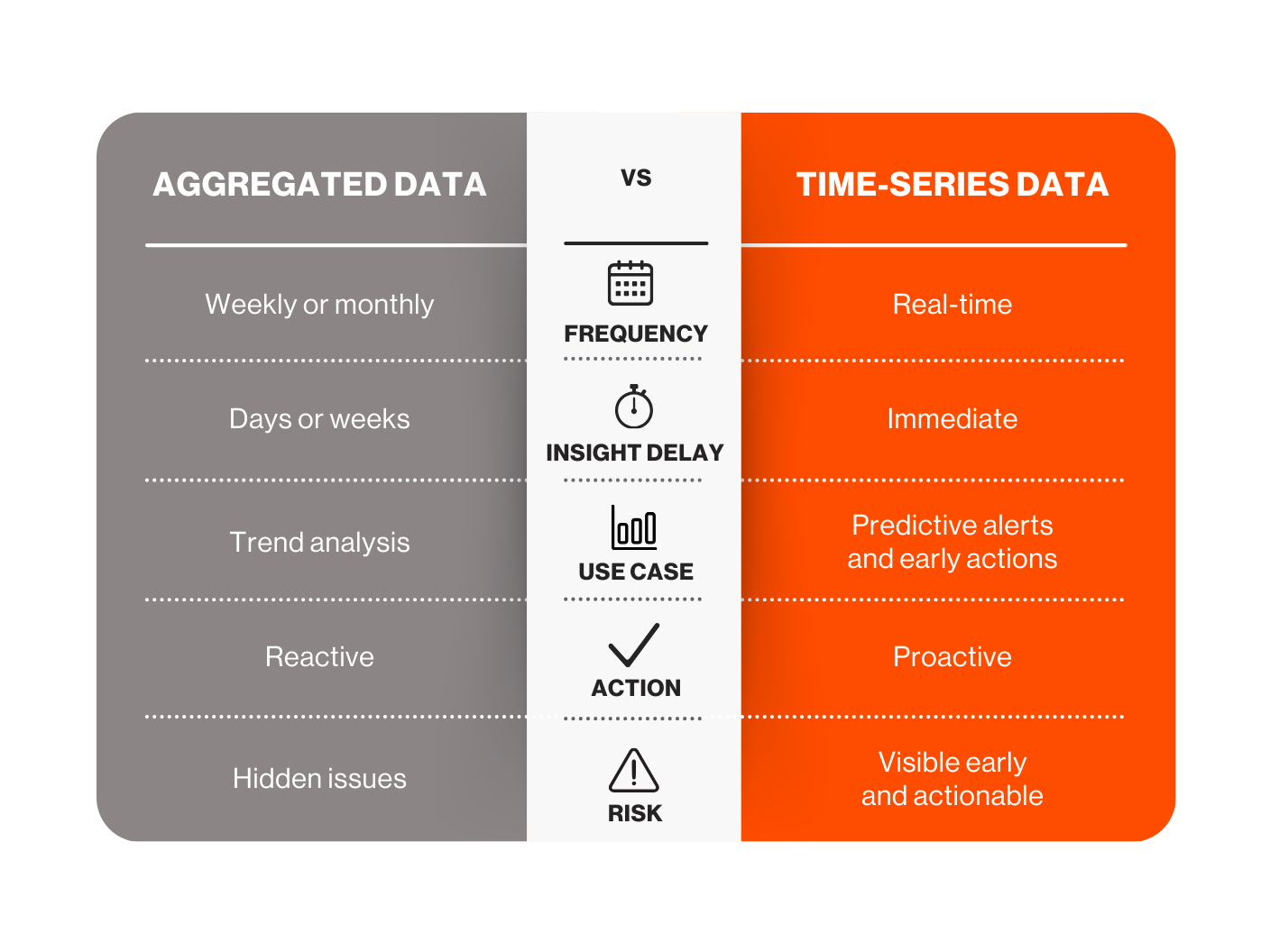

Why Continuous Time-Series Data Beats Aggregated Data

In predictive maintenance, the type of data you use makes all the difference.

Aggregated Data

- Summarizes trends over time (e.g., weekly or monthly averages)

- Great for reports and hindsight

Limitations: Delays decision-making, can mask underlying issues

Continuous Time-Series Data

- Captures live data at high frequency

- Enables real-time monitoring and anomaly detection

Advantage: Delivers early warnings before failures occur

Example:

A monthly vibration average for a centrifugal pump might look normal. But time-series data would show a sharp spike last Tuesday—an early warning for bearing failure that requires immediate attention.

Case Spotlight: Vitens – Becoming Data-Driven in Practice

Challenge

Vitens, the Netherlands’ largest drinking water company (serving 5.8 million customers, maintaining 50,000 km of pipelines, and operating 93 treatment plants), began with several disconnected pilots in its drive toward data-driven maintenance. These projects often lacked a clear connection to long-term strategy and didn’t consistently share insights across the organization UReason.

Approach

To scale up effectively, Vitens:

- Set up a central multidisciplinary project team (including IT, maintenance, field technicians, engineers, and management) to align pilots with broader business goals UReason.

- Started leveraging existing sensor infrastructure rather than reinventing it, and began appointing data managers to establish and maintain high data quality standards UReason.

- Strengthened IT collaboration, embedding IT specialists and data architects into the team to ensure shared platforms and policies underpinned predictive maintenance efforts UReason.

Results

At one pumping station pilot using continuous monitoring and advanced analytics, Vitens achieved a 7.1% efficiency gain, resulting in €2,500 in annual electricity savings and a CO₂ reduction of 9.2 tonnes—all through simple process adjustments and without costly hardware investments

This case shows that when change management meets continuous monitoring, the outcome is not just technical success—it’s measurable business value. Learn more about the case.

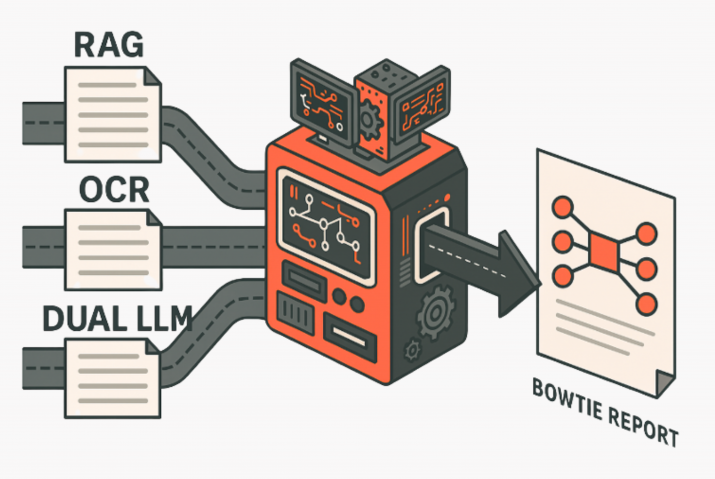

How UReason Enables Data-Driven Change

Vitens’ results highlight what’s possible when organizations align people, processes, and data with the right tools. This is exactly the role UReason’s APM Studio plays: providing the insights and integration needed to scale these successes across entire operations.

At UReason, we help organizations go from data-rich to insight-driven.

APM Studio:

- Connects with your existing data infrastructure (PI System, SCADA, CMMS, etc.)

- Surfaces leading indicators for early failure detection

- Empowers maintenance teams to shift from reactive to predictive planning

With APM Studio, your team can:

- Detect emerging problems in real time

- Prioritize maintenance actions based on risk and urgency

- Extend asset lifecycles and reduce unnecessary downtime

By embedding our solutions within your current tech stack, we ensure minimal disruption and maximum value from the start.

Conclusion: Predictive Maintenance Starts with People

Becoming data-driven is not just a technology project—it’s an organizational transformation.

Continuous time-series data gives visibility. Predictive tools like APM Studio provide clarity. But it’s change management that ensures this transition takes root.

Start with a pilot. Train your team. Show quick wins. And then scale with confidence.

Each step builds a culture where reliability, performance, and operational excellence are not reactive goals—but everyday realities.

Ready to take the first step?

Book a call with Artur Loorpuu, Senior Solutions Engineer in Digitalization. Artur specialises in turning industrial challenges into practical digital solutions through expertise in predictive maintenance, digital twins, data science, and strategic product management.

Let’s explore how we can support your goals!

5 Steps to Build a Predictive Maintenance Culture

5 Steps to Build a Predictive Maintenance Culture