Update: Since April 2024, UReason released a report on its research in Large Language Model and introduced its use case in implementing these models into Control Valve App. If you want to learn more about UReason’s advancement in implementing artificial intelligence in its products, see here.

Lately, all the pundits can’t talk enough about AI. That’s short for Artificial Intelligence. From ChatGPT to Industry 4.0, AI is supposed to solve everyone’s problems and, for all we know, fill your plant with miraculous and wonderful things.

Of course, that’s rubbish. AI is nothing but a tool. It isn’t even really “intelligence” per se. It is software that can be taught to do things by showing it examples and giving it rules and models rather than hard-coding every activity and result. Other terms you may have heard include “machine learning” and “simulation of human intelligence.”

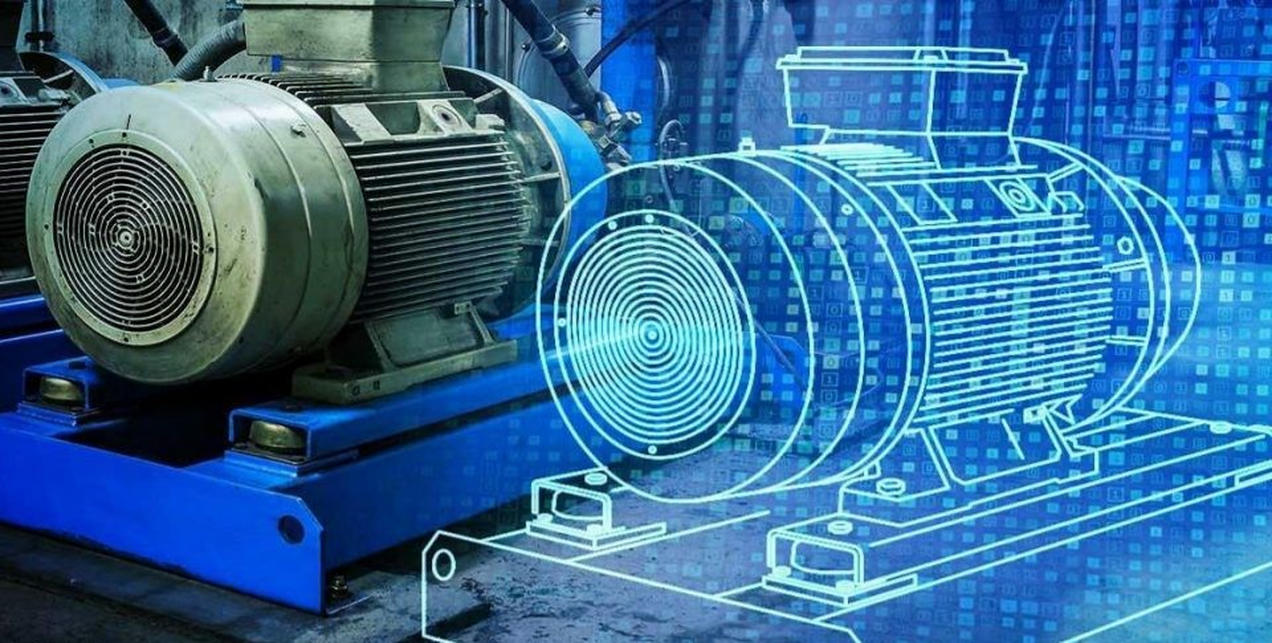

So how do you really use AI in your plant? You need to focus your attention and your efforts on what you really need. Before you do anything, you need to look around your plant for the things that give you pain and are likely to cause unplanned shutdowns or worse. You already know the answers—motors, drives, compressors, and above all, control valves.

These are almost always on the list of “bad actors” that will cause the plant manager to call the Chief of Maintenance at 3 a.m. in the morning. Most of those devices can provide immediate feedback when they fail and sometimes before they fail, but it is much harder to get that kind of feedback from control valves. That’s why most people do stroke testing (either full or partial stroke) on a regular basis. So do you, don’t you?

But how much of the “analysis” of your control valve failure patterns is still in your head? Intuition, educated guesses, and sometimes listening to the valve operate are part of the equation. But unless you have a really expensive prescriptive maintenance program, most of what you do is hit-and-miss. Sometimes you find the valve before it fails, sometimes the valve failure finds you.

Until now, it has been extremely complicated and extremely expensive to put together a system that will automatically check your valves and report their condition before they fail. This is where AI comes in.

An AI can be taught to determine when a valve is going to fail and when it will fail. And there’s a tool that does this just for control valves.

It is UReason’s Control Valve App—a simple, stand-alone app that will take the data you already have, and use it in an AI-based analysis engine to tell you which control valves will fail soon and when.

The Control Valve App (CVA) is based on UReason’s extensive expertise in valves, actuators, and the relevant processes. It uses intelligent models that combine domain knowledge and artificial intelligence (AI) to provide immediate detailed analysis of the process and recommendations for control valves. In the basic app, a PDF report is the output, while the premium version can have an online dashboard and provide job orders in the maintenance management system of the plant.

You can use UReason’s intelligence in a single application, like the CVA, or in an enterprise version, UReason’s APM Studio to manage all of your process and all your varied types of assets.

The CVA will allow you to switch from reactive maintenance to data-driven prescriptive maintenance. It will reduce unplanned repairs, and even better, it will help you postpone significant replacements, based on the actual remaining lifetime of the valve or actuator.

Are you interested to learn more about the benefits and functionalities of the app? You can download the brochure by filling in the form below or try our free interactive demo.

Download Control Valve App brochure

Get more information about how Control Valve App can optimize your valve maintenance and operations.