Industrial organizations generate vast amounts of time-series data every second. Hidden in that data are insights that can improve reliability, efficiency, and asset performance — but only if the data is accessible and usable.

This is where AVEVA PI and AVEVA CONNECT come into play, especially when paired with advanced analytics applications like the UReason Control Valve App.

Introducing AVEVA PI: The Backbone of Industrial Time-Series Data

AVEVA PI (formerly OSIsoft PI System) has been the gold standard for industrial time-series data management for decades.

A Brief History

Originally developed in the 1980s by OSIsoft, the PI System was designed to collect, store, and contextualize high-frequency operational data from industrial assets, such as sensors and control and information systems. Over the years, it evolved into a mission-critical platform for real-time operational intelligence. In 2021, OSIsoft joined AVEVA, further strengthening PI’s role in modern industrial ecosystems.

What Is AVEVA PI?

At its core, AVEVA PI is a time-series data infrastructure. It:

- Collects real-time data from sensors, control systems, and equipment

- Stores high-resolution historical data

- Provides context so data can be understood and analyzed

Who Uses AVEVA PI?

AVEVA PI is trusted across asset-intensive industries, including: Oil & Gas, Chemicals, Power & Utilities, Mining & Metals, Pulp & Paper and Manufacturing. For many organizations, PI is the single source of truth for operational data and servers as the foundation for data-driven operations:

- Eni uses the AVEVA PI System to build a digital oil field, optimizing real-time production and asset performance (case study).

- Abu Dhabi National Oil Company (ADNOC) leverages PI to enhance operational visibility and drive digital transformation across its energy operations (case study).

- Todd Energy uses the PI System to centralize real-time emissions and flow data, improving reporting accuracy and operational compliance (case study).

- Bristol-Myers Squibb uses AVEVA PI for real-time process monitoring and fault detection to ensure batch success in pharmaceutical manufacturing (case study).

- GlaxoSmithKline uses AVEVA System Platform alongside PI as the foundation for real-time manufacturing visibility and “Factory of the Future” initiatives (case study).

- Biogen uses the AVEVA PI System to improve production visibility and increase yield for Alzheimer’s drug manufacturing at scale (case study).

These examples show how PI has become mission-critical infrastructure across industries. But while PI excels at collecting and contextualizing operational data, making that data easily available for analytics, reporting, and external applications remains a challenge.

Extracting Time-Series Data from AVEVA PI

While AVEVA PI excels at collecting and storing data, extracting that data for analytics, reporting, or external applications can be challenging.

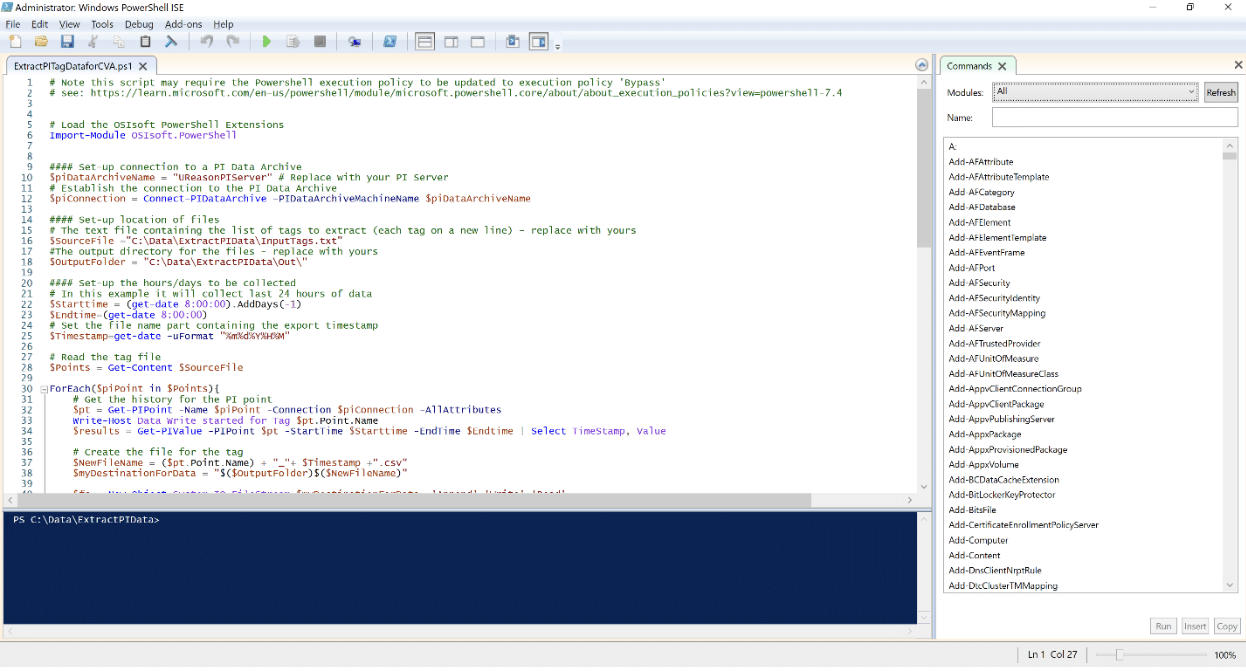

The common data extraction methods for the AVEVA PI system are the PI SDK / AF SDK, the PI Web API and Custom scripts (Python, PowerShell, etc.). These methods require deep PI-specific knowledge, custom development and ongoing maintenance. We often help teams get up and running quickly by providing a ready-to-use Powershell script that simplifies extracting time-series data from AVEVA PI. But continue reading there is an even easier way to get data securly from AVEVA PI with less effort!

Making PI Data Easier to Access with AVEVA CONNECT

As industrial organizations modernize, many are looking for more scalable, secure, and cloud-enabled ways to access PI data. This is where AVEVA CONNECT comes in.

What Is AVEVA CONNECT?

AVEVA CONNECT is AVEVA’s cloud-based industrial intelligence platform. It provides:

- Centralized data access across sites

- Cloud-scale analytics and visualization

- Secure data sharing across teams and applications

Instead of building point-to-point integrations, CONNECT creates a unified data layer that applications can consume easily.

Security by Design

Security is a core strength of AVEVA CONNECT:

- End-to-end encryption for data in transit and at rest

- Role-based access control ensures users see only what they’re authorized to see

- Cloud-native security standards aligned with enterprise IT and OT requirements

This allows organizations to safely expose PI data beyond the control room — without compromising operational integrity.

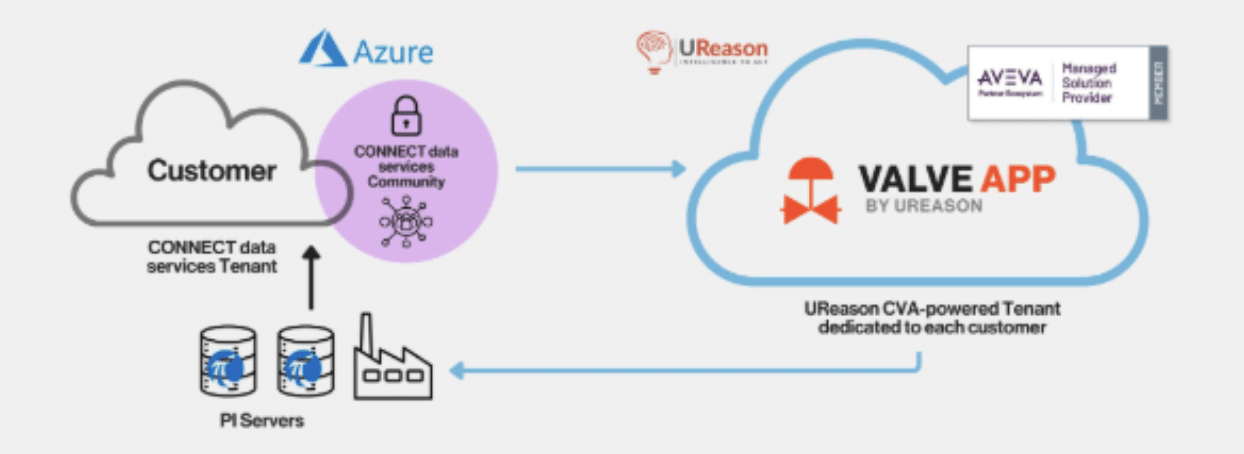

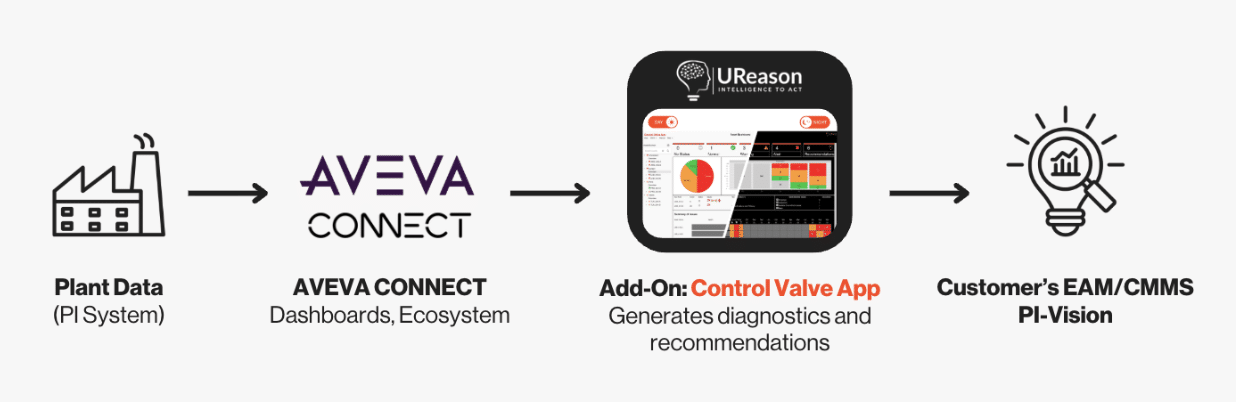

The Power of Synergy: AVEVA CONNECT and the UReason Control Valve App

When AVEVA CONNECT is combined with advanced analytics applications like our Control Valve App, its value multiplies.

The UReason Control Valve App leverages:

- High-quality time-series data from AVEVA PI

- Secure, scalable access via AVEVA CONNECT

- Advanced diagnostics and AI-driven analytics

Together, CONNECT and UReason enable:

- Faster deployment without complex integrations

- Secure access to valve data across sites

- Proactive detection of valve issues before failures occur

- Closing the feedback loop to your EAM and CMMS systems

Note that we use the AVEVA CONNECT Community. This is a feature within the AVEVA CONNECT industrial platform that allows companies to securely share and collaborate on real-time operational data with trusted partners, suppliers, and customers. The result is better asset health, improved reliability, and measurable operational savings.

Conclusion

AVEVA PI remains the foundation of industrial time-series data, but the way organizations use that data is evolving. By simplifying data extraction, leveraging AVEVA CONNECT for secure access, and integrating advanced analytics like the UReason Control Valve App.

By combining valve diagnostics, process data, and advanced analytics in one secure platform, the Control Valve App on AVEVA CONNECT enables you to:

- Identify control valve performance issues early before they lead to failures or downtime

- Continuously monitor valve health using live and historical data

- Detect hidden problems such as stiction, wear, air supply issues, and tuning deviations

- Prioritize maintenance based on actual valve condition, not time-based assumptions

- Prepare for turnarounds with confidence, reducing surprises and scope growth

- Improve reliability, safety, and maintenance efficiency across your assets

Whether your goal is to increase uptime, reduce maintenance costs, or improve turnaround planning, AVEVA CONNECT — combined with the Control Valve App — provides clear, actionable insights that help your teams move from reactive to predictive maintenance.

Explore How to Turn AVEVA PI Data into Actionable Insights

Contact us today to try the Control Valve App on AVEVA™ CONNECT and see how early issue detection can transform your control valve monitoring and turnaround preparation. Schedule a call with Artur Loorpuu, Senior Solutions Engineer in Digitalization, to learn more.

Industrial data is only powerful when it’s accessible — now is the time to make it work harder for you.