The Situation

SUEZ SA is a French-based utility company which operates largely in the water and waste management sectors. The company has its head office in La Défense, Paris. As a global expert in the water and waste sectors, SUEZ cities and industries in the circular economy to preserve, optimize and secure the natural resources.

The Challenge

The challenge is that operators at one of the waste water plant of SUEZ in Paris had too many alarms. This vast amounts of alarms and events is preventing them to have insight in the real priorities, detect abnormalities at the earliest possible stages and act accordingly.

The Solution

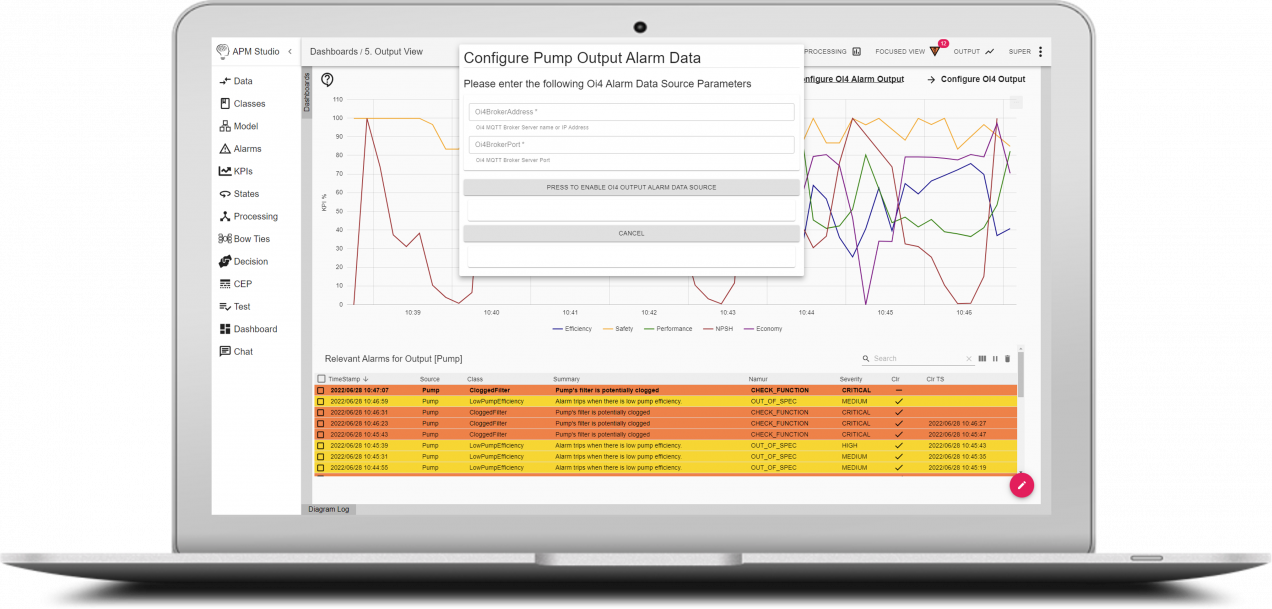

UReason offered APM Studio to support SUEZ. Within APM Studio, Advanced Alarm Management (Alarm Expert) offers amongst others the following functionality:

- Real-time analysis of the root causes of the current flows of events and alarms.

- Setting new rules for Alarm Management to reduce the amount of events and alarms by detecting patterns, sequences etc.

- Prioritize the different alarms and determine specific events that require (immediate) action.

- Automate the alarm management process, routing and escalating process and integrate with other software for external actions.

The Benefits

With daily reports on the alarm system’s behaviour now providing insights into where problems occur, operators were better to resolve them.

Automating the alarm management process led to significant efficiency by replacing many manual tasks: more than 80% reduction of the alarms.

By using reports produced by the software indicating what actions to take, SUEZ was able to reduce the number of incidents in the plant, and achieving a significant cost saving in many hours of operators, potential damages to assets and idle time.

Learn More About This Solution

Want to know more about APM Studio and how it can support your production?